Transparent soap equipment

Transparent soap equipment

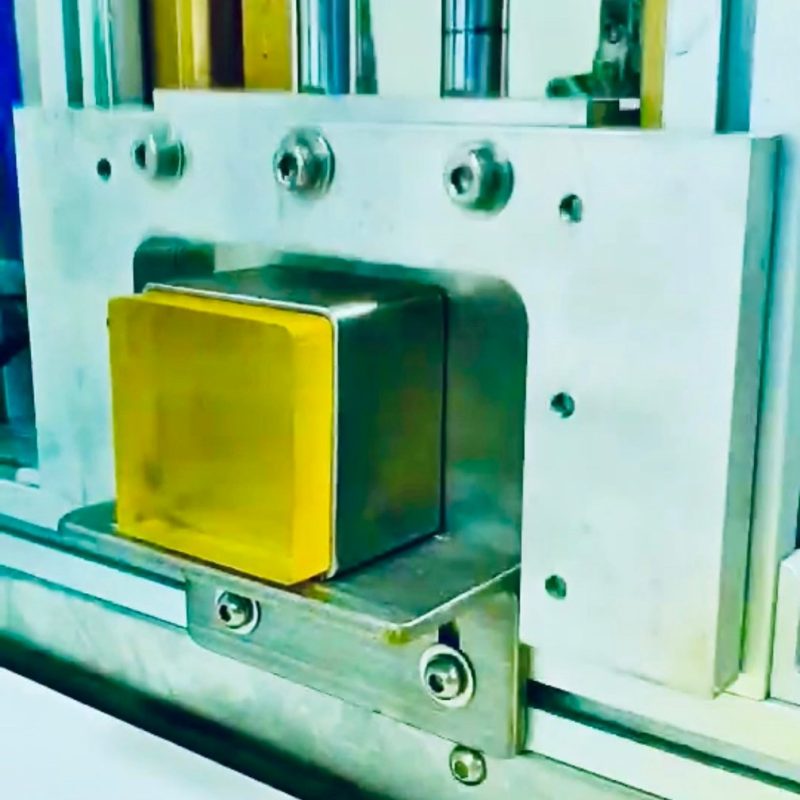

In the saponification process, adding glycerin or alcohol and other alcohol-based additives allows for the orderly arrangement of soap molecules, imparting transparency to the soap. In the pre-processing stage, a mixture of fats, fatty acids, and alkali solution is heated in a stirring vessel for saponification. Once the reaction is complete, the soap solution is poured into shaping molds and left to cool and solidify. After the soap solution has fully solidified, an extrusion and cutting machine is used to demold and cut the soap into blocks.

In the post-processing stage, the soap blocks are fed into a machine to remove the matte surface layer, and an automatic stamping machine or printer is employed to imprint trademarks and names. Standardized production processes can be tailored for different customers, effectively increasing production capacity and product quality.