Cold Process Soap Equipment

Cold process soap equipment

Soap has evolved into various forms, with cold process soapmaking being one of the earliest and continuously used methods. In this method, fats and alkali are saponified while maintaining a certain temperature. An emulsifying machine is used to stir the mixture until it reaches a creamy consistency, which is then poured into molds and kept warm to sustain the saponification reaction.

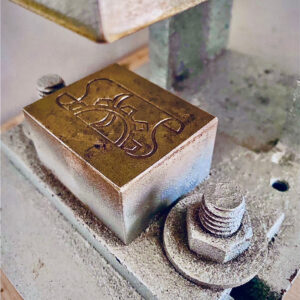

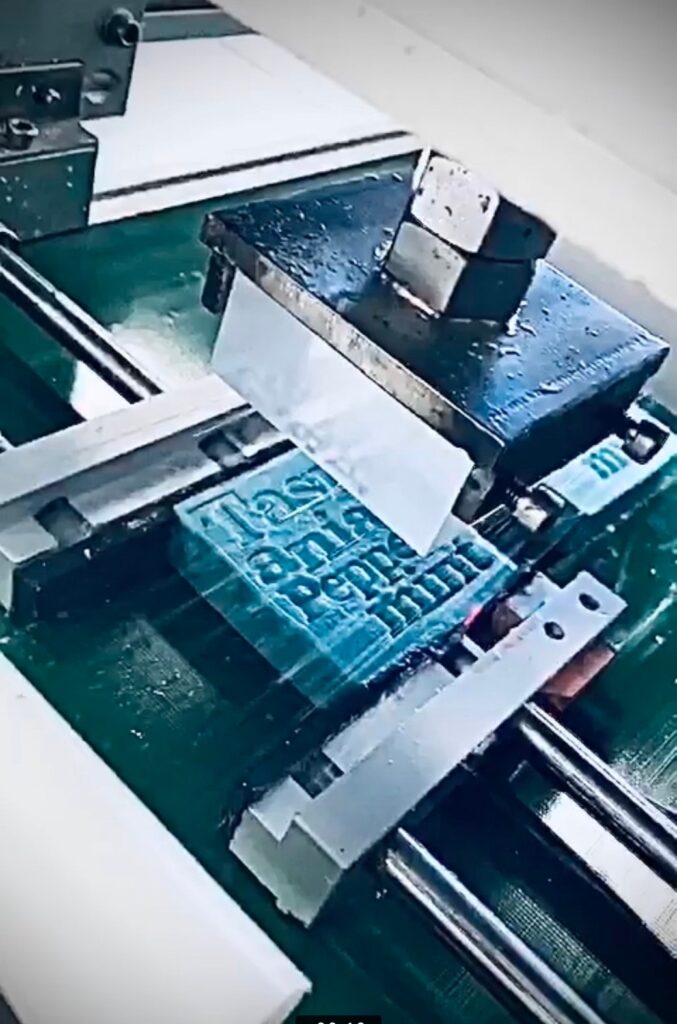

Once the soap inside the molds achieves a certain hardness, it can be demolded. A cutting machine is then used to cut the soap into blocks. These soap blocks are placed in a temperature and humidity-controlled room for curing and drying, a process known as saponification and drying. After the soap blocks reach a safe level of free alkali, an automatic stamping machine or printer is employed to imprint trademarks and names.

Customized standardized production processes can be developed for different customers, effectively enhancing production capacity and product quality.