Chalking

Chalking

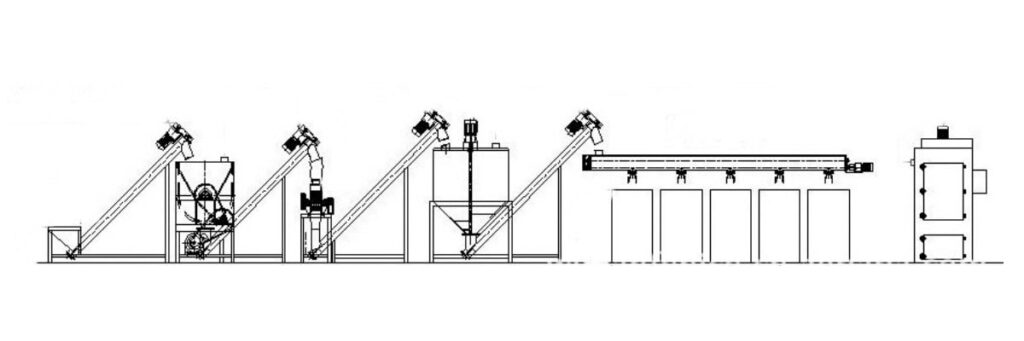

The production and forming processes of laundry powder mainly include the high tower spray drying method and the agglomeration method.

The high tower spray drying method involves mixing the raw materials of the laundry powder with water to create a slurry with the appropriate consistency. This slurry is filtered and pressurized, then sprayed into the top of a drying tower. At the bottom of the tower, hot dry air is introduced.

Inside the drying tower, the descending droplets of laundry powder slurry make full contact with the rising hot air, drying the powder into hollow granules, which are then ready for packaging.

The agglomeration method can be divided into types such as stirred agglomeration and air stream agglomeration, based on the fluidization of solid powder.

In the agglomeration method, certain materials in the laundry powder formula are mixed in specific proportions and then granulated using granulation equipment. The granules are then ground and sifted, and the powder is conveyed to a packaging machine for packaging.

Powder packaging machines are suitable for automatic packaging of fine powders that are not easily flowable into small bags. These machines can automatically complete bag making, measurement, filling, sealing, and weight sorting, with precise design to ensure the maximization of product quality and output.